About Dolphin Pipe

The Dolphin Poly Plast Pvt. Ltd, based in Rajkot is most prominent and efficient manufacturers of HDPE pipes and Micro Irrigation System.

During the past few years we have transformed our business, changing the way we do things. I consider that as a major strategic leap forward. We expect our people to make the best decisions for the group as a whole and lot just their little part of it. I consider this as important because the thrust of our activity has been to view business in a much more global way. Our aim is to pull together our world-wide strength in order to service both stable and growing markets, within existing as well as new customers. Our customers are now seeing the benefits of our working as a global team and each day we look forward to meet new opportunities and challenges.

Dolphin Pipe Services

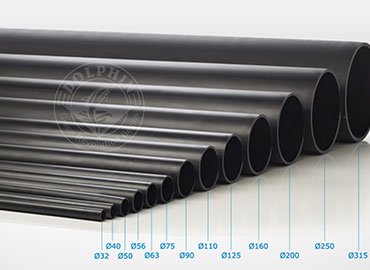

DOLPHIN is one of the most leading manufacturers and exporters of a phenomenal range of HDPE pipes, IRRIGATION pipes, SPRAY pipes and pipe fittings.

Product Gamut

We are one of the industrial pioneers and leaders in the plastic industry. The Director of the company enjoys a rich experience of 25 years in the field of manufacturing HDPE pipes, irrigation pipe, sprinkler pipe, sprinkler fittings spray pipes and micro irrigation system pipes and fittings.

read more

Production unit

The production unit is based at Metoda GIDC, Rajkot, Gujarat, established in year 1999. Our infrastructure includes 4200 sq. ft. manufacturing facility consisting of state of the art & machinery, a separate Quality Control department and R & D dept. All our products are ISI marked.

read more

Certification

The quality of our products coupled with our customer centric approach has helped us to garner a wide base of clients. Dolphin is well known for its commitment to quality and has the coveted ISI Mark for its entire range and all units are ISO 9001 certified.

read more

Drip Irrigation System

Drip Irrigation System Mini Sprinkler Irrigation System

Mini Sprinkler Irrigation System Sprinkler Irrigation System

Sprinkler Irrigation System HDPE Pipes

HDPE Pipes  Spray Pipe

Spray Pipe  MDPE Pipe

MDPE Pipe HDPE PLB Duct

HDPE PLB Duct c-PVC Pipe & Fittings

c-PVC Pipe & Fittings u-PVC Pipe & Fittings

u-PVC Pipe & Fittings PVC Pipe & Fittings

PVC Pipe & Fittings SWR Pipe & Fittings

SWR Pipe & Fittings PVC Garden Pipe

PVC Garden Pipe Column Pipe

Column Pipe